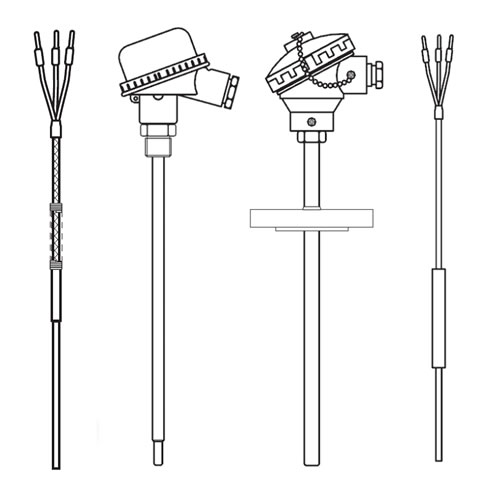

WORKING PRINCIPLE

The working principle for metaI resistance thermometers, normally called thermoresistances, is bases on the variation of the electrical resistance of a metal with variations in the surrounding temperature.In the industrial field the materials most frequently used are platinum and nickel which, due to their high resistivity and stability, permit the production of thermoelements which are highly reproducible, small and with excellent dynamic characteristics.

The temperature measurements carried out with thermoresistances are far more precise and reliable than those carried out with other types of sensor such as thermocouples or thermomistors.

Normally resistance thermometers are identified with the code of the material used to construct them (platinum = Pt, nickel = Ni etc.) followed by their nominal resistance at a temperature of 0°C .

The range of use of industrial resistance thermometers is between -200 e +850°C as given in the table.

MEASURING METHODS

There are different methods for connecting the resistance thermometers to the measuring devices, the choice of one method rather than another basically depends on the precision required in the measurement.Resistances thermometers connection techniques

• A 2 wires

• A 3 wires

• 4 wires with compensation

• 4 wires volt-ammeter

The two-wire technique is the least precise and is used only in cases where the connection of the thermoresistance is carried out with short and low resistivity wires; indeed testing the equivalent electrical circuit, it can be noted that the electrical resistance measured is the sum of that of the sensitive element (and, therefore, dependent on the temperature being measured) and the resistance of the conductors used for the connection. The error introduced with this type of measurement is not constant: it depends on temperature.

Due to the good degree of precision obtainable in measurements, the three-wire technique is the most used in the industrial field. With this measurement technique the errors caused by the resistance of the conductors used for the connection of the thermoresistance are eliminated; at the output of the measuring bridge the voltage present depends entirely on the variation of the resistance of the resistance thermometer and consequently only on the temperature.

The technique of four wires with compensation is little used nowadays since it was only used in potentiometric measuring circuits in order to eliminate the error introduced by the resistance of the conductors used in the connection.

The volt-ammeter four-wire technique offers the greatest precision possible; little used in the industrial field, it is almost exclusively used in laboratory applications. On an equivalent electrical circuit it can be seen that the voltage measured depends solely on the resistance of the thermoelement; the precision of the measurement depends exclusively on the stability of the measuring current and the precision of the voltage reading across the thermoelement.